In my original post on promotional printing, I highlighted some of the key printing press innovations. Movable type, lithography and offset printing drove the creation of a whole industry that revolutionized how books and other mass-produced communications were created for public consumption.

The use of offset press technology for promotional printing became widespread around 1950 and remained relatively unchanged until the early 1990s. If you didn’t need variable data, but required high quality black and white or full color printing, you pretty much had to use offset presses. The purpose of this post is to highlight the decision points clients faced using offset press technology and the reasons digital print technologies blew up their world.

Promotional print workflow was different

Through the 1980s, there were very defined lines between promotional and transactional print. Much of it had to do with the use of variable data, but the bigger barrier was the actual workflow. Transactional print utilized data from mainframe computers, and you could print the entire job on demand on a line printer or the newer production digital printers. In other words, you could send a 20-page document to the printer and print the pages in order without issue. The printers could be easily connected to mainframes and supported the mainframe data formats. I documented the workflow in more detail on my transactional printing posts here and here.

Promotional printing didn’t use variable data and utilized higher quality print in both black and white and full color. As such, promotional printing relied on offset press technology which used a workflow that relied on three distinct phases listed below:

- Pre-Press: All the steps and procedures prior to the actual printing. This would include designing the page layout, creating print plates and setting up the printer.

- Press: The actual work of putting the black and white or full color image on the preferred substrate.

- Post Press: All finishing work for the printed page: collation, binding, folding and other specialized finishing services.

Most offset presses are sheet-fed – meaning they feed one sheet of paper and print one image at a time. If you needed 500 copies of a promotional document, you printed 500 copies of page one, then 500 copies of page two and so on. For longer run lengths of 5,000 or 10,000, your vendor might move the work to an offset press that could handle larger page quantities. This allowed you to put multiple images of the same page on the plate which dramatically increased print productivity. No matter what size press was used, business owners had to make a series of decisions that had significant impact on the cost and turnaround of their promotional printing. Let’s walk through a few of them in each workflow step:

Pre-Press: All the steps and procedures prior to the actual printing. This would include designing the page layout, creating print plates and setting up the printer.

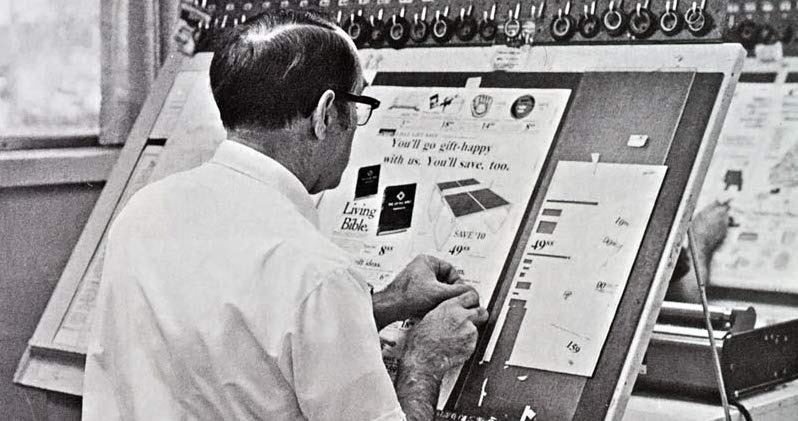

- Page Layout: Each page had to be laid out. Prior to digital workflows and widespread adoption of personal computers, this was a manual process. And when I say manual that means you had a skilled operator manually cutting and pasting images and sections of text on a page. For every single page of the manual!

- Plate making: If you printed in black and white, you needed one print plate per page. If you printed the job in full color, you needed four plates per page. One for cyan, magenta, yellow and black. Four plates meant more work and cost for page layout.

- Printer Set Up: Each time you ran one page, the plate had to be mounted on the press and test pages run. If you ran full color, all four plates had to be mounted on a four-color press and set up so all four images aligned perfectly. This process was repeated for every page of the printed document.

Press: The actual work of putting the black and white or full color image on the preferred substrate. Once the press ran, the cost per page was low. You paid for paper and ink.

Post Press: All finishing work for the printed page: collation, binding, folding and other specialized finishing services.

- Collation: The printed pages were collated in order to make complete documents. Typically completed on machines. Oversize pages had to be manually inserted at a higher cost.

- Finishing: Binding, folding and the drilling of holes in the paper for insertion into 3-ring binders and so on.

This is simplifying a lot of these steps. The key take away is the pre-press is expensive, while the printing is relatively cheap. And post press can be expensive. These steps factored heavily into the decisions the client made.

- Black and white or full color: One plate versus four plates with four times the page creation and printer setup. Full color printing cost more.

- Paper type: Regular paper or coated, high gloss or higher quality stock? All affect cost.

- Run length: How many copies? Given the high cost of pre-press and low cost of printing, you didn’t want to run out of copies and need to run the job again with all the pre-press costs.

- Finishing: Special covers? Binding like three-hole punch or spiral? How about packaging? Shrink wrapped? Shipping? Storage of unused copies?

- Lead time: Very few of these jobs completed in one day. You could pay for expedited service, but the upcharge was high. Every decision you made on B/W or color, paper stock, finishing and more affected the turnaround time. This workflow was not set up for last minute jobs.

Think of promotional print workflow as print and distribute. You printed a lot of copies, distributed most of them and stored the extras which created a whole new set of problems. Where do you store them? What happens when the document changes? Do you throw away all the stored copies and start new? The point is: traditional promotional printing generated cost at every step. The printing was the initial cost. And storage, waste and distribution continued to generate cost.

What happened?

There were a variety of trends that put pressure on this workflow including the increased pace of change. There was a growing need to change promotional documents on a more frequent basis. That didn’t work well with print and store workflow. Companies wanted to run fewer copies of each document – and the cost of pre-press made the per piece cost expensive on short run lengths. More and more companies wanted to print promotional documents on demand like you could in transactional print workflows. The market responded.

In 1990, Xerox paired their production print technology with a built-in scanner and digital front ends to create the DocuTech 135 printer. This device combined the pre-press, print and post press elements into an electronic workflow, launching the Print on Demand Market. In the early 1990s, there was also widespread adoption of desktop computers and the development of desktop-based publishing software. This allowed clients to create their own promotional documents and send them to network connected DocuTechs.

This growth in network connected desktop computers, followed by widespread use of the Internet and mobile phones, literally blew up the promotional print ecosystem. Now you could deliver communications in a wide variety of formats and channels. This set the stage for the evolution of multi-channel communications we take for granted today. It also blurred the lines between transactional and promotional communications – a topic I’ll explore on the next Flashback Friday post.

No Comments